Rubber seals play a vital role in automobiles. Their excellent elasticity, wear resistance, oil resistance and other properties enable them to effectively prevent the leakage of various liquids, isolate dust and noise, and provide a certain buffering effect. .

In the industrial field, rubber seals are indispensable for maintaining the integrity, efficiency, and safety of equipment across a wide range of sectors.

In the drinking water system, it is directly related to human safety and health. In addition to waterproofing, chemical resistance and non-toxicity, the product selection must take into account the characteristics such as waterproofing, chemical resistance and non-toxicity. Regular inspection and replacement are also an important part of ensuring hygiene.

Rubber seals are fundamental in ensuring the safe and effective operation of medical devices, contributing to patient safety, device reliability, and improved healthcare system.

Rubber seals are the essential component in precision machinery, which its durability and sealing's properties can ehance the performance of sensitive precision machinery

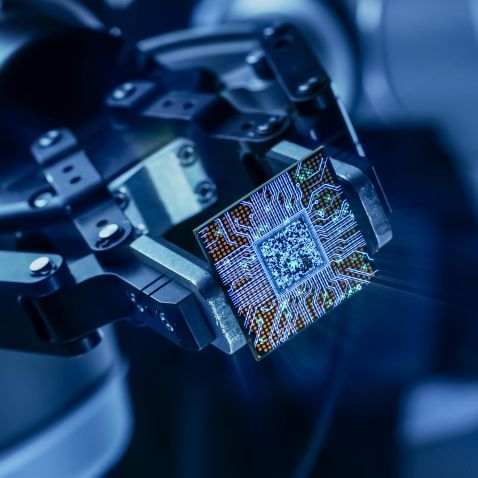

Rubber seals primarily with the property of various chemicals resistance, which contribute to the efficiency, reliability, and cleanliness of semiconductor manufacturing processes.

Rubber parts provide durability, flexibility, and resistance to wear and environmental factors, which can improve agricultural machinery'sefficiency and productivity and labor savings.

Rubber seals are essential in the oil and gas field to ensure equipment integrity, prevent leaks, and maintain safe, efficient operations. Their applications span multiple areas, each with specific requirements due to the extreme conditions encountered, such as high pressures, temperatures, and exposure to harsh chemicals.

Verification

Click the numbers in sequence.