Self-Mixing Compounds In Percentage

V Rings: An Overview and Introduction

V rings are rubber components installed on rotating shafts, named for their V-shaped cross-section, also known as V-ring/V-packing. They are a type of rotary seal used for shafts.

Below, we will introduce each one in turn:

- The function of v rings

- The key benefits of v rings

- Material specification of v rings

- Type of v rings

- Installation of V rings

- General rules of V rings

- V rings size list

The Function of V rings

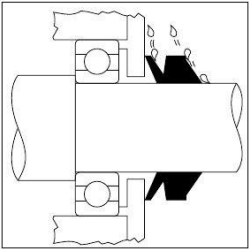

The function of V rings is to exclude dirt, water, or other aggressive media from entering bearing housings while also retaining grease. The V rings stretch over the shaft and assume a tight interference fit.

V rings shaft seals utilize centrifugal slinger action to provide effective protection against dry and wet contamination. In combination with a metal-cased radial seal, the V-ring reduces wear and extends the service life of the oil seal and bearings.

V rings also perform well in dry running applications. Because it is all rubber and very elastic, it can be stretched over flanges or other components for easy installation with minimal unit disassembly. It has very low torque drag and heat build up, and does not require expensive counter surface preparation.

The Key Benefits of V rings

Technical simplicity

Low friction and minimal loss of power. In smaller power units this can be significant. The pressure of the lip against the counterface is very light.

Economical

Wide machining tolerances-little or no shaft finishing. No housing required. No shaft wear. Seals resist damage during installation. One size covers many shaft sizes.

Versatile application

Works equally well on rotating or oscillating shafts and at high speeds over 3000 FPM. At high speeds the lip lifts away from the counterface and acts as a clearance slinger.

Material specification of V rings

Standard materials:Nitrile and Fluoroelastomer

Non-standard materials:Hydrogenated nitrile, Silicone, Chloroprene and Ethylene propylene

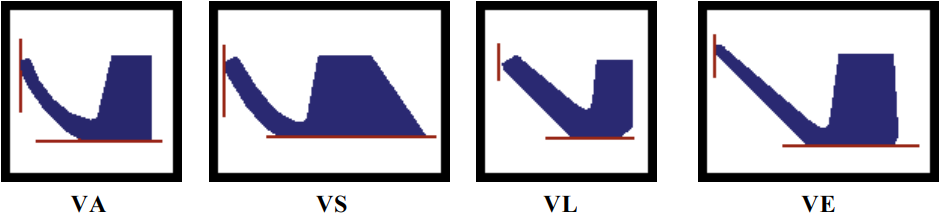

Type of V rings

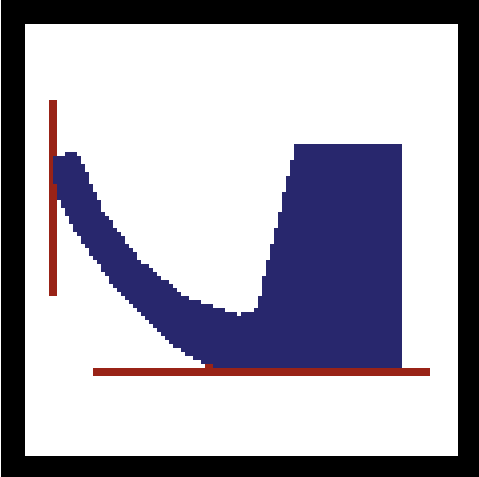

The VA type

The most common style available in the widest range of sizes from .110" (2.7mm) shaft to 79.530" (2020mm) nitrile and fluoroelastomer. Ideal for protecting gearboxes, electric, motors and drives.

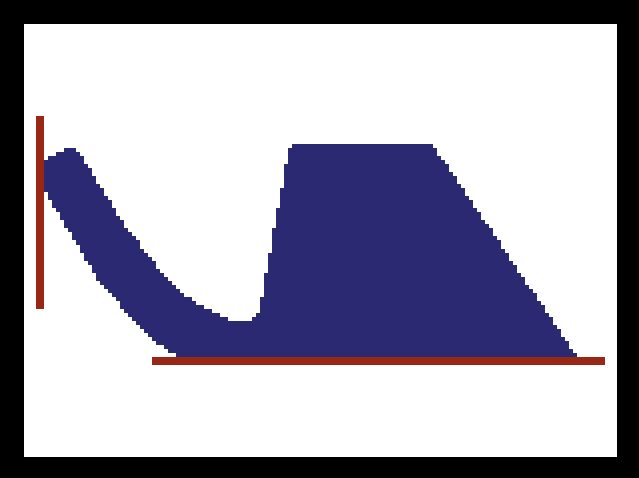

The VS type

The original V-ring was designed with a wide body and tapered heel to firmly hold the ring on the shaft. Available in sizes from .180" (4.5mm) shaft to 8.270" (210mm). Commonly used in agricultural and automotive applications.

The VL type

Very compact axial cross-section commonly used in confined spaces to replace labyrinth seals. Available in nitrile and fluoroelastomer for shaft sizes from 4.134" (105mm) shaft to 78.745" (2000mm) and beyond.

The VE type

A heavy-duty large diameter style commonly used in rolling mills as a secondary seal for heavy duty applications where the primary seal has to be protected against water and or particulate contamination. VR4 is the preferred heavy duty. Available in both nitrile and fluoroelastomer for shafts from 11.811" (300mm) to over 78" (2000mm).

Installation of V rings

Where the V rings are used as a grease seal/contaminant excluder, the V rings are normally mounted on the outside of a bearing housing with axial support when required.

In the case of mass production, it is always advisable to use an assembly tool. Where small quantities are involved the V-ring may be fitted by using a blunt instrument, such as a screwdriver, to manipulate the seal into the correct position.

General rules of V rings:

- The V-ring, the counterface and the shaft should be clean.

- The shaft should preferably be dry and free from grease or oil.

- The lip of the V-ring should be lubricated with a thin film of grease or silicone oil.

- Ensure that the V-ring is mounted with a uniform stretch around the shaft.

V RINGS SIZE LIST

Type:VA

| VA No. | Shaft Range | Inside Diameter | Width | Height |

|---|---|---|---|---|

| VA-3 | 2.7-3.5 | 2.5 | 1.5 | 3 |

| VA-4 | 3.5-4.5 | 3.2 | 2 | 3.7 |

| VA-5 | 4.5-5.5 | 4 | 2 | 3.7 |

| VA-6 | 5.5-6.5 | 5 | 2 | 3.7 |

| VA-7 | 6.5-8 | 6 | 2 | 3.7 |

| VA-8 | 8-9.5 | 7 | 2 | 3.7 |

| VA-10 | 9.5-11.5 | 9 | 3 | 5.5 |

| VA-12 | 11.5-13.5 | 10.5 | 3 | 5.5 |

| VA-14 | 13.5-15.5 | 12.5 | 3 | 5.5 |

| VA-16 | 15.5-17.5 | 14 | 3 | 5.5 |

| VA-18 | 17.5-19 | 16 | 3 | 5.5 |

| VA-20 | 19-21 | 18 | 4 | 7.5 |

| VA-22 | 21-24 | 20 | 4 | 7.5 |

| VA-25 | 24-27 | 22 | 4 | 7.5 |

| VA-28 | 27-29 | 25 | 4 | 7.5 |

| VA-30 | 29-31 | 27 | 4 | 7.5 |

| VA-32 | 31-33 | 29 | 4 | 7.5 |

| VA-35 | 33-36 | 31 | 4 | 7.5 |

| VA-38 | 36-38 | 34 | 4 | 7.5 |

| VA-40 | 38-43 | 36 | 5 | 9 |

| VA-45 | 43-48 | 40 | 5 | 9 |

| VA-50 | 48-53 | 45 | 5 | 9 |

| VA-55 | 53-58 | 49 | 5 | 9 |

| VA-60 | 59-63 | 54 | 5 | 9 |

| VA-65 | 63-68 | 58 | 5 | 9 |

| VA-70 | 68-73 | 63 | 6 | 11 |

| VA-75 | 73-78 | 67 | 6 | 11 |

| VA-80 | 78-83 | 72 | 6 | 11 |

| VA-85 | 83-88 | 76 | 6 | 11 |

| VA-90 | 88-93 | 81 | 6 | 11 |

| VA-95 | 93-98 | 85 | 6 | 11 |

| VA-100 | 98-105 | 90 | 6 | 11 |

| VA-110 | 105-115 | 99 | 7 | 12.8 |

| VA-120 | 115-125 | 108 | 7 | 12.8 |

| VA-130 | 125-135 | 117 | 7 | 12.8 |

| VA-140 | 135-145 | 126 | 7 | 12.8 |

| VA-150 | 145-155 | 135 | 7 | 12.8 |

| VA-160 | 155-165 | 144 | 8 | 14.5 |

| VA-170 | 165-175 | 153 | 8 | 14.5 |

| VA-180 | 175-185 | 162 | 8 | 14.5 |

| VA-190 | 185-195 | 171 | 8 | 14.5 |

| VA-199 | 195-210 | 180 | 8 | 14.5 |

| VA-200 | 190-210 | 180 | 15 | 25 |

| VA-220 | 210-235 | 198 | 15 | 25 |

| VA-250 | 235-265 | 225 | 15 | 25 |

| VA-275 | 265-290 | 247 | 15 | 25 |

| VA-300 | 290-310 | 270 | 15 | 25 |

| VA-325 | 310-335 | 292 | 15 | 25 |

| VA-350 | 335-365 | 315 | 15 | 25 |

| VA-375 | 365-390 | 337 | 15 | 25 |

| VA-400 | 390-430 | 360 | 15 | 25 |

| VA-450 | 430-480 | 405 | 15 | 25 |

| VA-500 | 480-530 | 450 | 15 | 25 |

| VA-550 | 530-580 | 495 | 15 | 25 |

| VA-600 | 580-630 | 540 | 15 | 25 |

Type:VS

| VS No. | Shaft Range | Inside Diameter | Width | Height |

|---|---|---|---|---|

| VS-5 | 4.5-5.5 | 4 | 2 | 5.2 |

| VS-6 | 5.5-6.5 | 5 | 2 | 5.2 |

| VS-7 | 6.5-8 | 6 | 2 | 5.2 |

| VS-8 | 8-9.5 | 7 | 2 | 5.2 |

| VS-10 | 9.5-11.5 | 9 | 3 | 7.7 |

| VS-12 | 11.5-13.5 | 10.5 | 3 | 7.7 |

| VS-14 | 13.5-15.5 | 12.5 | 3 | 7.7 |

| VS-16 | 15.5-17.5 | 14 | 3 | 7.7 |

| VS-18 | 17.5-19 | 16 | 3 | 7.7 |

| VS-20 | 19-21 | 18 | 4 | 10.5 |

| VS-22 | 21-24 | 20 | 4 | 10.5 |

| VS-25 | 24-27 | 22 | 4 | 10.5 |

| VS-28 | 27-29 | 25 | 4 | 10.5 |

| VS-30 | 29-31 | 27 | 4 | 10.5 |

| VS-32 | 31-33 | 29 | 4 | 10.5 |

| VS-35 | 33-36 | 31 | 4 | 10.5 |

| VS-38 | 36-38 | 34 | 4 | 10.5 |

| VS-40 | 38-43 | 36 | 5 | 13 |

| VS-45 | 43-48 | 40 | 5 | 13 |

| VS-50 | 48-53 | 45 | 5 | 13 |

| VS-55 | 53-58 | 49 | 5 | 13 |

| VS-60 | 58-63 | 54 | 5 | 13 |

| VS-65 | 63-68 | 58 | 5 | 13 |

| VS-70 | 68-73 | 63 | 6 | 15.5 |

| VS-75 | 73-78 | 67 | 6 | 15.5 |

| VS-80 | 78-83 | 72 | 6 | 15.5 |

| VS-85 | 83-88 | 76 | 6 | 15.5 |

| VS-90 | 88-93 | 81 | 6 | 15.5 |

| VS-95 | 93-98 | 85 | 6 | 15.5 |

| VS-100 | 98-105 | 90 | 6 | 15.5 |

| VS-110 | 105-115 | 99 | 7 | 18 |

| VS-120 | 115-125 | 108 | 7 | 18 |

| VS-130 | 125-135 | 117 | 7 | 18 |

| VS-140 | 135-145 | 126 | 7 | 18 |

| VS-150 | 145-155 | 135 | 7 | 18 |

| VS-160 | 155-165 | 144 | 8 | 20.5 |

| VS-170 | 165-175 | 153 | 8 | 20.5 |

| VS-180 | 175-185 | 162 | 8 | 20.5 |

| VS-190 | 185-195 | 171 | 8 | 20.5 |

| VS-199 | 195-210 | 180 | 8 | 20.5 |

Type:VL

| VL No. | Shaft Range | Inside Diameter | Width | Height |

|---|---|---|---|---|

| VL-0120 | 115-125 | 108 | 6.5 | 10.5 |

| VL-0130 | 125-135 | 117 | 6.5 | 10.5 |

| VL-0140 | 135-145 | 126 | 6.5 | 10.5 |

| VL-0150 | 145-155 | 135 | 6.5 | 10.5 |

| VL-0160 | 155-165 | 144 | 6.5 | 10.5 |

| VL-0170 | 165-175 | 153 | 6.5 | 10.5 |

| VL-0180 | 175-185 | 162 | 6.5 | 10.5 |

| VL-0190 | 185-195 | 171 | 6.5 | 10.5 |

| VL-0200 | 195-210 | 182 | 6.5 | 10.5 |

| VL-0220 | 210-233 | 198 | 6.5 | 10.5 |

| VL-0250 | 233-260 | 225 | 6.5 | 10.5 |

| VL-0275 | 260-285 | 247 | 6.5 | 10.5 |

| VL-0300 | 285-310 | 270 | 6.5 | 10.5 |

| VL-0325 | 310-335 | 292 | 6.5 | 10.5 |

| VL-0350 | 335-365 | 315 | 6.5 | 10.5 |

| VL-0375 | 365-385 | 337 | 6.5 | 10.5 |

| VL-0400 | 385-410 | 360 | 6.5 | 10.5 |

| VL-0425 | 410-440 | 382 | 6.5 | 10.5 |

| VL-0450 | 440-480 | 405 | 6.5 | 10.5 |

| VL-0500 | 480-530 | 450 | 6.5 | 10.5 |

| VL-0550 | 530-580 | 485 | 6.5 | 10.5 |

| VL-0600 | 580-630 | 540 | 6.5 | 10.5 |